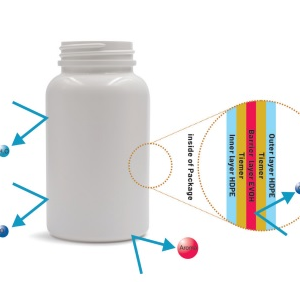

Tiemer L321D is an advanced adhesive resin meticulously formulated with a polyethylene base, specifically crafted to excel in packaging applications.

Applications of the adhesive

Tiemer L321D is a groundbreaking adhesive resin, meticulously engineered to meet the exacting demands of various packaging applications. Its maleic anhydride grafted PE-based composition makes it an ideal choice for fostering strong adhesion between polyethylene (PE) and polyamide (PA) or ethylene vinyl alcohol (EVOH) in blown and cast film processes.

Blown Film Applications: In blown film applications, Tiemer L321D excels at creating robust bonds between different substrates. Its specialized formulation ensures reliable adhesion, contributing to the overall integrity and performance of the blown film. The resin’s compatibility with PE and PA or EVOH enables the production of films with enhanced structural stability and barrier properties.

Cast Film Applications: When it comes to cast film production, Tiemer L321D takes center stage. Its unique characteristics enable seamless adhesion between PE and PA or EVOH layers, fostering the creation of high-quality cast films. The resin’s superior performance in cast film applications extends to its ability to enhance film properties, including tensile strength and elongation.

Double-Bubble Applications: Tiemer L321D is specifically tailored for double-bubble applications, where adhesion between different layers is crucial. The resin’s maleic anhydride grafted PE base ensures a strong bond between PE and PA or EVOH, contributing to the structural integrity and overall performance of double-bubble structures. Whether in the production of packaging materials or industrial applications, Tiemer L321D is the adhesive resin of choice for achieving outstanding results.

In summary, Tiemer L321D stands as a versatile solution for a spectrum of packaging applications, from blown and cast films to intricate double-bubble structures. Its adaptability and superior adhesion properties make it an indispensable component in the pursuit of high-quality and reliable packaging solutions. Elevate your packaging endeavors with the unmatched capabilities of Tiemer L321D.

Key Characteristics

Physical Characteristics of the adhesive

- Melt Flow Rate: 1.90-3.5 g/10min

- Hardness: 43-46 Shore D

- Density: 0.91-0.92 g/cm3

Peel Strength

Adhesion Strength of Aluminum Sandwich (Al/Tiemer/Al = 0.3/0.1/0.3 mm) (Heat Seal Condition: t=180s, T=220 °C)

- Plateau: 110-140 N/20mm

- Peak: 75-110 N/20mm

Mechanical

- Tensile Strength: 9-11 MPa

- Elongation @ Break: 430-500%

Thermal

- Melting Point: 120 °C

Packaging & Storage Conditions: Tiemer L321D is thoughtfully packaged in 25kg bags, ensuring convenience in handling. For optimal performance, it is recommended to store this resin in a dry and dust-free environment at room temperature. Exercise caution by keeping it away from incompatible materials, as well as food and beverages. Elevate your packaging solutions with Tiemer L321D, the epitome of innovation in adhesive resins.