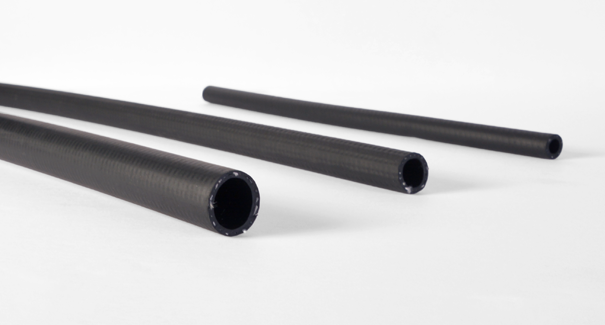

Experience the next level in thermoplastic vulcanization with our TPV 35D-B, a cutting-edge solution meticulously designed for Injection Molding, Blow Molding, and Extrusion applications. Crafted from EPDM/PP, this dynamically vulcanized TPV boasts an array of features that set it apart in the industry.

Key Features of TPV 35D-B

- Excellent Ozone Resistance: With a robust formulation, TPV 35D-B ensures exceptional resistance against ozone, enhancing its durability in diverse environments.

- Good Flex Fatigue: Engineered to withstand flex fatigue, this TPV guarantees long-lasting performance, making it ideal for applications with repetitive mechanical stresses.

- UV Stabilized: The UV stabilization of this type of TPV ensures that it maintains its structural integrity when exposed to prolonged sunlight, offering reliability in outdoor applications.

- Natural and Black Color Options: Tailor your projects with ease, as this type of TPV is available in both natural and black color variations.

Applications

Versatility meets precision with TPV 35D-B, making it the material of choice for various applications, including:

- Automotive Interiors and Exteriors: Delivering performance under the hood and beyond.

- Industrial Settings: Meeting the demanding requirements of industrial applications.

- Wire & Cable: Ensuring reliability in electrical and cable management systems.

Key Characteristics

Mechanical Integrity OF TPV 35D-B

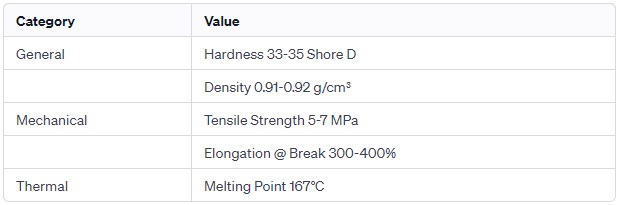

This type of TPV stands out with its remarkable mechanical properties, providing a hardness of 33-35 Shore D for exceptional resilience and structural stability.

Its tensile strength ranging from 5-7 MPa ensures robust performance under varying mechanical loads, making it an ideal choice for applications where strength and durability are paramount.

The elongation at break, ranging from 300-400%, signifies the material’s ability to flex and adapt without compromising its structural integrity, contributing to its longevity in demanding environments.

Precision in General Characteristics

In the realm of general characteristics, TPV 35D-B sets a benchmark with a density of 0.91-0.92 g/cm³, striking the perfect balance between lightweight flexibility and structural integrity. This characteristic makes it well-suited for applications where weight considerations are crucial without sacrificing performance.

The meticulous engineering of this type of TPV ensures that it meets the stringent requirements of various industries, offering a versatile solution that excels across a spectrum of demanding applications.

Thermal Performance OF TPV 35D-B

TPV 35D-B excels in thermal performance, boasting a 167°C melting point that ensures robust heat resistance. This quality is vital in automotive and industrial settings, where components face high temperatures. The material retains its structural integrity in challenging thermal conditions, making it a dependable choice for under-the-hood applications. It guarantees consistent performance in environments with fluctuating temperatures, solidifying its reputation as a high-performance thermoplastic vulcanized material in both automotive and industrial sectors.

All values provided are typical and should not be construed as real specifications. Users are encouraged to confirm results through their tests.

Packaging & Storage Conditions

TPV 35D-B comes in 25kg bags for convenient handling. Store it in a dry, dust-free room at room temperature for optimal performance. Exercise caution, keeping this TPV away from incompatible materials, food, and drink.

Elevate your projects with the advanced capabilities of TPV 35D-B, setting a new standard in thermoplastic vulcanization.