Introduction

Tiemer resins are functionalized polyethylene (PE), designed for bonding incompatible materials, such as polyamides (PA), ethylene vinyl alcohol (EVOH), polyester, and metals (e.g., aluminum). They are also used as coupling agents and compatibilizers in various types of composite compounds. Specifically, these maleic anhydride grafted polyethylene (PEg-MA) resins, known for their versatility and compatibility, serve as effective tie layers in applications ranging from packaging to agriculture.

Tiemer resins can be easily processed as any other polyolefin (e.g., extrusion) and make multilayer structures such as films, sheets, bottles, pipes, tubes, and others, help to combine the excellent properties of incompatible materials, for example, gas barrier resin and moisture barrier resins.

The Versatility of Tiemer Resins

Composition and Processing of Tiemer Resins

Food packaging plays a pivotal role in safeguarding the integrity of food products throughout the entire distribution chain. Without appropriate packaging, the processing and quality of food can be compromised due to direct exposure to physical, chemical, and biological contaminants.

Food manufacturers, recognizing the significance of maintaining freshness, employ packaging strategies aimed at shielding their products from oxygen, odor, and moisture. Plastic packaging emerges as a highly effective solution for this purpose, offering numerous advantages to consumers, suppliers, and society at large.

In addition to conventional packaging methods, the utilization of multilayer structures incorporating Tiemer resins further enhances the protective capabilities of packaging materials. This includes the creation of barriers against oxygen, moisture, and aroma, as well as the implementation of modified atmosphere packaging (MAP), resulting in a substantial extension of shelf life.

Packaging Prowess

Tiemer resins, specifically designed for packaging applications, find wide-ranging use in the production of multilayer films, casings, pouches, tubes, bottles, and containers. Employing standard Tiemer grades, such as 0221S for multilayer bottles and tubes, and L321D for multilayer films (utilizing the double bubble process), ensures the consistent application of high-quality tie layers in the packaging industry. This commitment to standardized grades reflects the dedication to optimal performance and reliability in various packaging processes, including co-extrusion blown (double bubble process), cast film, and tube co-extrusion methods.

Industrial Applications of Tiemer Resins

Corrosion Prevention

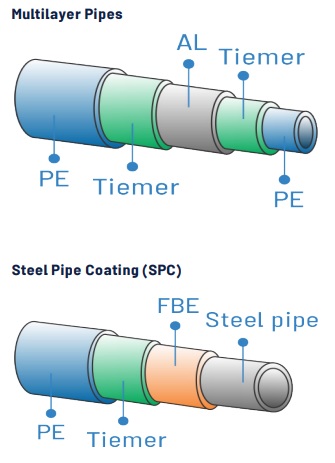

Within the construction industry, various heating/cooling systems have emerged, with recent advancements featuring the development of barrier pipes, offering substantial advantages such as corrosion inhibition. Specifically utilized in heating systems, a barrier pipe represents a plastic water conduit engineered to impede the penetration of oxygen into the material, thus mitigating the risk of corrosion. This barrier is typically comprised of a resin material strategically bonded between the outer and inner layers of the pipe. Material options for the pipe include crosslinked PE, PE-RT, PP, or PB-1.

Addressing corrosion concerns in steel pipelines used for water and chemical fluids transportation, a preventive measure involves coating the steel pipe with polymer layers. This protective coating system typically encompasses three layers: a fusion-bonded epoxy (FBE) applied to the surface of the steel pipe, an adhesive (Tie-Layer), and a top coat crafted from polyolefin materials.

In both instances, Tiemer assumes a crucial role as the tie layer resin, contributing indispensable attributes to the integrity and performance of the constructed systems.

Plumbing Excellence

The advantages of Tiemer in multilayer pipes and SPC (steel pipe coating) applications are multifaceted, including:

- Strong adhesion

- Adhesion durability

- Polyethylene-like processability

- High flex fatigue resistance

- Adhesion/cohesion balance

For plumbing applications, Tiemer is available in standard grades, tailored to specific needs:

- 0500 M7: Designed for outer layers of multilayer pipes

- L621O: Tailored for inner layers of multilayer pipes

- 0500: Ideal for steel pipe coating applications

This comprehensive utilization of Tiemer in various construction applications underscores its versatility and reliability as a tie layer resin, contributing to the longevity and performance of heating/cooling systems and steel pipelines within the construction domain.

Tiemer’s Role in Aluminum Composite Panels

Contemporary architectural designs frequently incorporate aluminum panels to embellish the exteriors of buildings, leveraging the aesthetic appeal, cost-effectiveness, and lightweight characteristics of such claddings. Typically, these panels are composed of multilayer structures, combining aluminum with polyethylene (PE).

A sandwich panel, constituting a pivotal element in these structures, is characterized by a three-layer composition. This includes a low-density core, flanked by thin skin-layers bonded to each side. Ensuring optimal bonding strength between the aluminum facing and the polyethylene core necessitates the use of tie layer adhesives.

In the realm of architectural applications requiring robust bonding solutions, Tiemer assumes significance. Available in both pellet and film forms, Tiemer serves as a key component in this context, facilitating the cohesive integration of aluminum and polyethylene layers within the sandwich panel structure. The versatile forms of Tiemer contribute to the structural integrity and longevity of these composite panels, thereby enhancing their overall performance in modern construction practices.

Tiemer Resins’ Significance in Agriculture

Mulch Films

Mulch films serve a multifaceted purpose in agriculture, contributing to the nuanced management of soil conditions. These films play a vital role in temperature regulation, weed suppression, moisture retention, and the enhancement of crop yield and precocity. Typically composed of polyethylene blends, their efficacy in optimizing agricultural outcomes is well-established.

However, the fumigation process, while essential for crop health, poses potential health risks to field workers and nearby residents. To mitigate these concerns and minimize environmental impact, a strategic optimization of fumigation is imperative. High-barrier films, characterized by 5 to 7 layers incorporating polyamide or EVOH as a barrier layer, have been innovatively designed for this purpose. Notably, within these advanced film structures, Tiemer functions as a pivotal tie layer, ensuring both efficacy and environmental safety.

Silage Films

Silage films play a crucial role in the preservation and storage of forage, silage, hay, grain, and maize, particularly in regions where the growth period of herding grass is limited. Employing a multilayer barrier film approach, these films aim to safeguard natural nutritional values while creating impermeability to water and exhibiting a controlled oxygen permeation rate. In the construction of multilayer silage films, Tiemer stands out as a key tie layer, contributing to the structural integrity and functional performance of the film.

Agro-Chemical Bottles

The formulation of agrochemical bottles demands a meticulous approach due to the potential interactions between chemical substances and plastics. These bottles are constructed with multilayer structures, necessitating a robust barrier layer such as EVOH or PA to resist the diffusion of chemical agents, including fertilizers. Crucially, a solid tie layer is essential to ensure a secure bond between the barrier and polyolefin layers. In this specific application, Tiemer serves as the preferred tie layer, providing both structural cohesion and chemical resistance, thereby enhancing the integrity of agrochemical bottle constructions.

Handling, Processing, and Disposal of Tiemer Resins

Handling and Storage of Tiemer Resins

Drying

The non-hygroscopic nature of Tiemer sets it apart, as it absorbs minimal moisture compared to non-polyolefin polymers. Consequently, Tiemer eliminates the need for pre-processing drying, streamlining the manufacturing process.

Disposal

Tiemer’s environmentally responsible characteristics extend to its end-of-life considerations. This versatile resin can be effectively reused, recycled, or incinerated with energy recovery, aligning with sustainable waste management practices. It is strongly advised against disposing of Tiemer in landfills or introducing it into the environment. The emphasis is on responsible disposal methods to mitigate environmental impact.

Processing Parameters of Tiemer Resins

Temperatures and Shutdown of Tiemer Resins

Processing

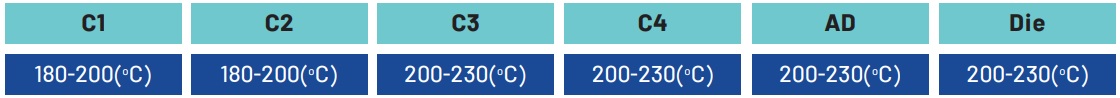

The recommended temperatures for Tiemer are as follows:

When processing Tiemer, adherence to recommended temperatures is imperative for optimal results. The maximum temperature threshold is set at 300 oC. It is crucial to note that exceeding this upper limit or subjecting the molten resin to prolonged residence times may induce polymer decomposition.

Decomposition Consequences

In the event of polymer decomposition, the resultant by-products may include carbon monoxide, carbon dioxide, hydrocarbons, and water. Understanding and managing these potential outcomes is vital for maintaining both the integrity of the material and the safety of the processing environment.

Shutdown Protocol

A meticulous shutdown procedure is recommended when the extrusion process is either interrupted or terminated. If the interruption spans less than 2 hours, stopping screw rotation while maintaining temperature is advised. For interruptions exceeding 2 hours, a thorough purging and shutdown, following established industry procedures, are recommended to ensure a smooth resumption of operations.

Purging

For permanent shutdown scenarios, the use of low-density polyethylene (LDPE) is recommended as the purging material, with an extrusion temperature ranging between 200-230 oC. This strategic purging process helps prevent material degradation and facilitates a seamless transition during shutdown periods, contributing to the longevity and efficiency of the overall processing system.

Conclusion

In conclusion, Tiemer resins have emerged as pivotal contributors across a spectrum of industries, providing an unparalleled fusion of compatibility, adhesion, and barrier properties. This unique amalgamation positions Tiemer as a cornerstone solution in addressing the intricate challenges associated with material incompatibility. Through its continuous evolution, Tiemer resins assert their transformative influence, elevating the performance and efficiency standards within diverse applications.